Temporary replacement 3 full is a term that’s gaining traction across various industries, and for good reason. It’s not just about filling gaps—it’s about ensuring continuity, efficiency, and success in both personal and professional settings. Whether you’re looking to replace a critical component, a team member, or even a system, understanding the nuances of temporary replacement can save you time, money, and headaches. So, why wait? Let’s dive into what this concept entails and how it can revolutionize the way you approach challenges.

In today’s fast-paced world, things don’t always go as planned. From unexpected breakdowns to sudden staff shortages, having a solid temporary replacement strategy is crucial. This guide will walk you through everything you need to know about temporary replacement 3 full, from its basics to advanced implementation techniques. Think of it as your go-to manual for navigating uncertainty with confidence.

Now, let’s be real—temporary replacement isn’t just about slapping a Band-Aid on a problem. It’s about finding the right fit, ensuring compatibility, and minimizing disruption. Whether you’re in manufacturing, healthcare, IT, or any other field, the principles remain the same. Ready to learn more? Let’s get started!

Read also:Condom Calculator Your Ultimate Guide To Finding The Perfect Fit

Understanding Temporary Replacement 3 Full

What Exactly is Temporary Replacement?

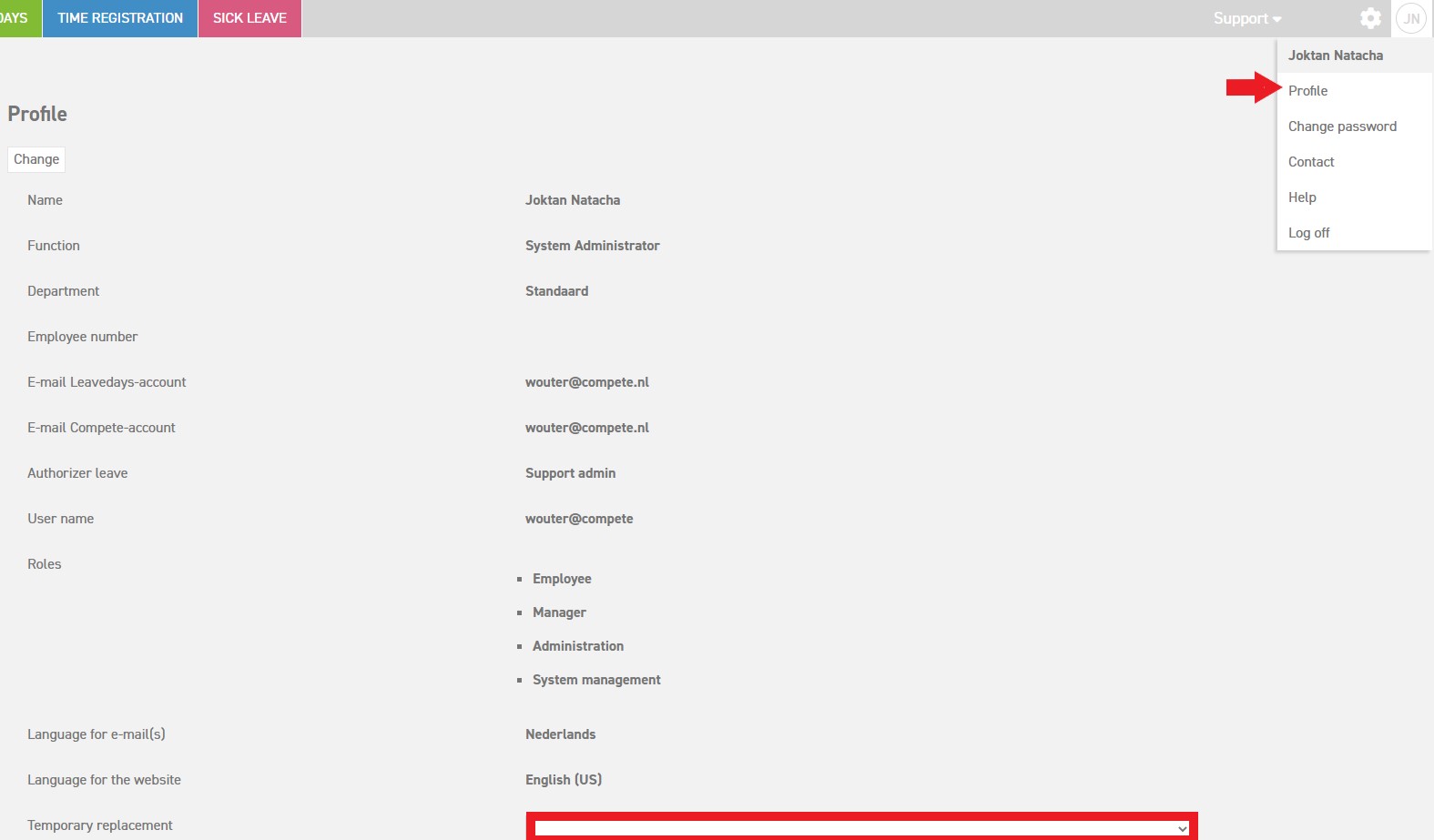

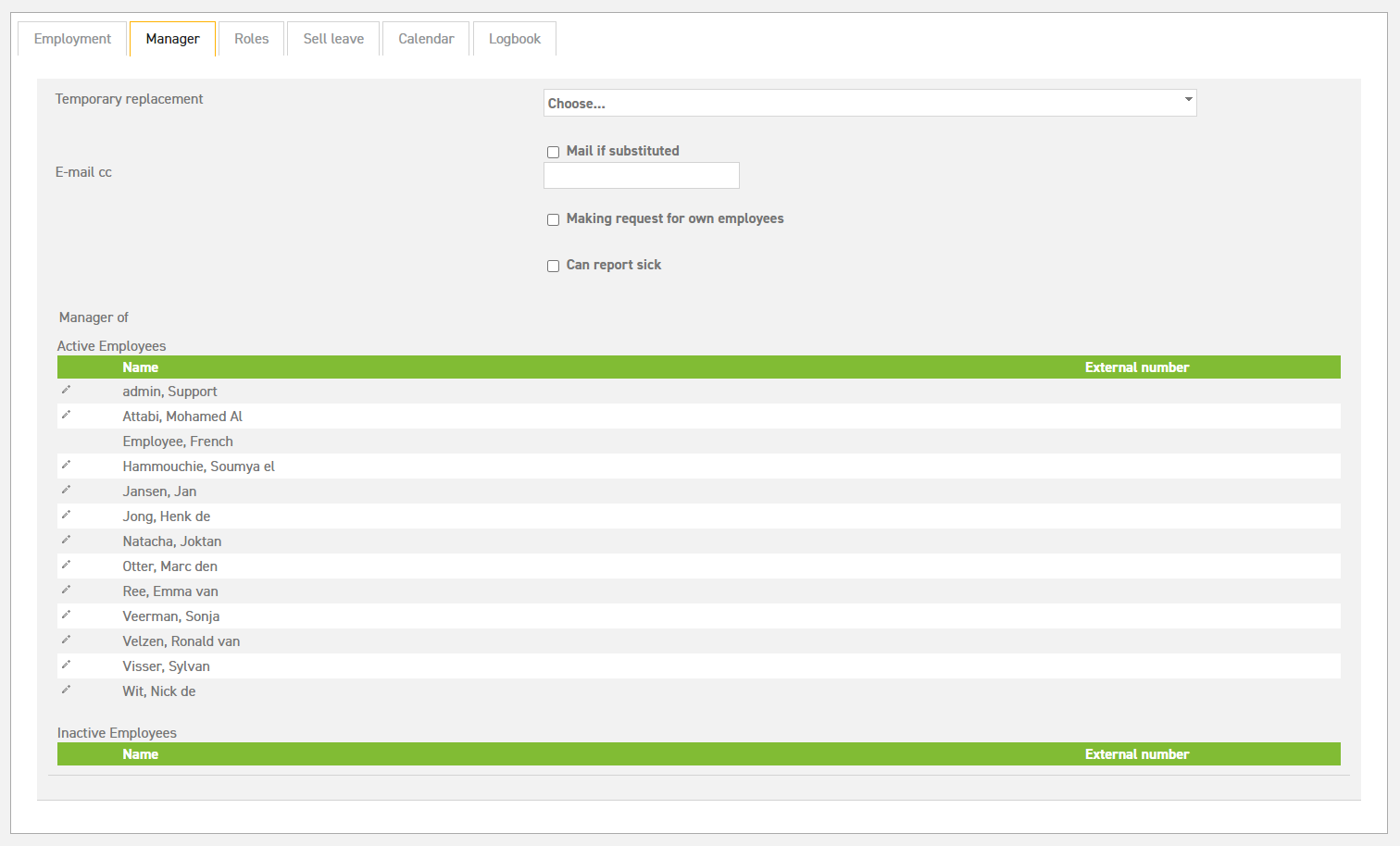

Temporary replacement refers to the process of substituting a resource, whether it’s a person, machine, or system, for a limited period until the original can be restored or replaced permanently. The “3 full” aspect highlights the importance of covering all three critical dimensions: functionality, performance, and integration. In simpler terms, it’s about ensuring the replacement can fully step into the role without compromising quality or output.

For instance, imagine a manufacturing plant where a key machine breaks down. A temporary replacement 3 full would involve finding a machine that not only performs the same function but also integrates seamlessly with existing systems and meets performance standards. It’s not just about getting something that works—it’s about getting something that works well.

Here’s a quick breakdown of what “3 full” entails:

- Functionality: Does the replacement perform the required tasks?

- Performance: Does it meet or exceed the expected output levels?

- Integration: Does it work harmoniously with existing systems and processes?

Why Temporary Replacement Matters

Addressing Unforeseen Challenges

Life—and business—are unpredictable. Temporary replacement 3 full becomes essential when you’re faced with unexpected disruptions. Whether it’s an employee taking sudden leave, a critical piece of equipment failing, or a software system crashing, having a reliable temporary solution can keep operations running smoothly.

Consider this scenario: a hospital’s MRI machine goes down during peak hours. Without a temporary replacement, patient care could suffer, leading to delays, dissatisfaction, and potentially even legal issues. By implementing a temporary replacement 3 full strategy, the hospital can ensure continuity of care while the permanent solution is being addressed.

Key Benefits of Temporary Replacement

Minimizing Downtime

One of the most significant advantages of temporary replacement 3 full is the ability to minimize downtime. In industries where every minute counts, such as logistics or healthcare, even a short disruption can have far-reaching consequences. By having a robust temporary replacement plan in place, you can reduce the impact of unforeseen events and maintain operational efficiency.

Read also:Kat Timpf New Baby Name The Cutest Addition To The Family

Additionally, temporary replacements allow you to test different options without committing to long-term changes. This flexibility can be invaluable when evaluating new technologies, processes, or personnel. For example, a company considering a switch to a new software platform might use a temporary replacement to assess its compatibility and effectiveness before making a permanent decision.

Implementing Temporary Replacement Strategies

Step-by-Step Guide

Implementing a successful temporary replacement 3 full strategy involves several key steps:

- Identify Needs: Clearly define what needs to be replaced and why.

- Evaluate Options: Research potential replacements that meet functionality, performance, and integration criteria.

- Test Compatibility: Ensure the replacement works seamlessly with existing systems.

- Monitor Performance: Continuously assess the replacement’s effectiveness and make adjustments as needed.

- Plan for Transition: Develop a clear plan for transitioning back to the permanent solution or making the temporary replacement permanent if necessary.

Each step is crucial to ensuring the success of your temporary replacement strategy. Skipping any of these stages can lead to inefficiencies, increased costs, or even failure to meet objectives.

Common Challenges and How to Overcome Them

Integration Issues

One of the most common challenges in temporary replacement 3 full is integration. Even if the replacement meets functionality and performance requirements, it may not integrate smoothly with existing systems. To overcome this, it’s essential to conduct thorough testing and involve all relevant stakeholders in the evaluation process.

For example, if you’re replacing a software system, ensure that all departments using the system are consulted and that any necessary training is provided. This proactive approach can help identify potential issues before they become major problems.

Data and Statistics Supporting Temporary Replacement

Industry Insights

According to a recent study by McKinsey, companies that implement effective temporary replacement strategies experience a 20% increase in operational efficiency. Additionally, a survey by Deloitte found that 75% of organizations believe temporary replacements are critical to maintaining business continuity.

These statistics highlight the importance of having a well-thought-out temporary replacement 3 full plan. By investing in the right solutions, companies can not only mitigate risks but also gain a competitive edge in their respective industries.

Best Practices for Temporary Replacement

Focus on Quality

When selecting a temporary replacement, quality should always be a top priority. While cost is an important factor, choosing a subpar replacement can lead to more problems down the line. Instead, focus on finding a solution that meets or exceeds your expectations in terms of functionality, performance, and integration.

Additionally, consider working with reputable suppliers or partners who have experience in temporary replacements. Their expertise can help ensure that you make the best possible choice for your specific needs.

Real-World Examples of Temporary Replacement

Case Study: Manufacturing Plant

A manufacturing plant in Ohio faced a major setback when one of its key machines broke down. Rather than halting production entirely, the plant implemented a temporary replacement 3 full strategy. They sourced a compatible machine from a nearby supplier, ensured it integrated with their existing systems, and trained their staff on its use. As a result, they were able to maintain production levels and avoid significant financial losses.

This case study demonstrates the power of having a well-prepared temporary replacement plan. By acting quickly and effectively, the plant was able to overcome a potentially devastating setback.

Future Trends in Temporary Replacement

Innovation in Solutions

As technology continues to evolve, so too do the possibilities for temporary replacement 3 full. Advances in artificial intelligence, machine learning, and robotics are opening up new avenues for creating more efficient and effective temporary solutions. For example, AI-powered systems can analyze data in real-time to recommend the best temporary replacement options, while robots can fill gaps in manual labor with precision and speed.

Looking ahead, it’s clear that temporary replacement will become even more integral to business operations. Companies that embrace these innovations will be better positioned to navigate the challenges of the future.

Conclusion

Temporary replacement 3 full is more than just a solution—it’s a strategy for success. By understanding its importance, implementing effective strategies, and staying ahead of industry trends, you can ensure that your operations remain smooth and efficient, no matter what challenges arise.

So, what’s next? Take action by reviewing your current temporary replacement plans, identifying areas for improvement, and exploring new solutions. And don’t forget to share your thoughts and experiences in the comments below. Together, we can build a community of knowledge and support around this vital topic.

Table of Contents

- Understanding Temporary Replacement 3 Full

- Why Temporary Replacement Matters

- Key Benefits of Temporary Replacement

- Implementing Temporary Replacement Strategies

- Common Challenges and How to Overcome Them

- Data and Statistics Supporting Temporary Replacement

- Best Practices for Temporary Replacement

- Real-World Examples of Temporary Replacement

- Future Trends in Temporary Replacement

- Conclusion